Email: info@swastikheavyelectricals.com

Swastik is the group of technocrats providing electrical engineering services in various fields presently based in Thane, India.This is a business vertical engaging specialised techniques in providing complete engineering including designs, drawings, testingetc.for manufacturing/Refurbishment of Transformers.Other services include transformer site overhauling, site testing, etc. pursuing the business goal of offering excellent quality services to the customer.

Vision: Our vision is to be the benchmark of electrical infrastructure industry & to be considered the trusted partner by our customers for creating value for them by providing best solutions & services.

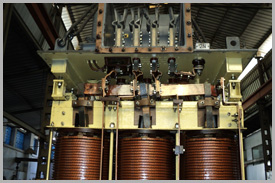

Infrastructure: Our advanced manufacturing & testing facility located at kalher Bhivandi near Thane, Maharashtra, India having -------- sq.ft. area has an installed capacity to manufacture /repair Power, Distribution & Special Transformers up to 10000 kVA & 33 kV class. Special transformers include Furnace, Rectifier, Earthing, Converter duty & Dry etc.

Design: Design validations and confirmation of safety, performance and reliability of the product is ensured with detailed testing of each product individually. Quality has been our culture right from the start. We have built it in our procedures which are implemented even before design begins – ensuring correct interpretation of customer requirements.At Swastik, we employ back our in-depth knowledge-experience in the transformer industry and green energy solutions. Along with the extensive experience of over three decades, with advanced design software linked with human intelligence and ISO practices we strive to provide highest quality. Our high tech solutions facilitate low energy loss with efficient and extended lifespan products meeting IEC & Indian Standards at international & national competitive prices with necessary services.

Testing: We have modern in house testing facility to conduct all routine tests as per IS 2026 & customer requirements.

Raw Materials: The majority input raw materials are sourced from leading global suppliers to ensure optimum performance.

The cores are made from high grade, cold rolled, grain oriented silicon steel, coated with magnesium Silicate-phosphate/carlite insulation. Core construction / stacking is such as to minimise eddy current losses resulting into reduction of no load losses.

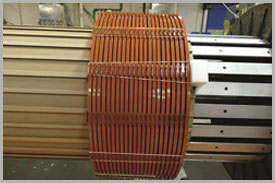

Windings are made of electrolytic copper conductor covered with insulation papers & are designed to meet three fundamental requirements of mechanical, thermal & electrical stress withstanding capacities, along with low energy loss practices.

Insulation materials are selected considering their electrical& mechanical strengths.

Transformer oil is used according to IEC 60296/ IS 335.

Active parts are protected with high mechanical strength & leak proof tank ensuring safety in withstanding internal & external fault pressures. Cooling Radiators or other cooling systems are provided such as ONAN/ONAF/OFAF/OFWF considering customer’s requirements.

Also, On load tap changers of reputed make are provided to ensure continuous quality power supply as needed.

Quality Control: Quality has always been inherent to our culture. Reliability, timely delivery and performance as parameters for customer satisfaction are continuously evolved and reviewed. Corrections in practices are also appropriately incorporated to meet requirements of ISO: 9001: 2008. We promote this approach through training for up gradation in capabilities and competitive skills.