A NEW DAWN IN CLEANING TECHNOLOGY

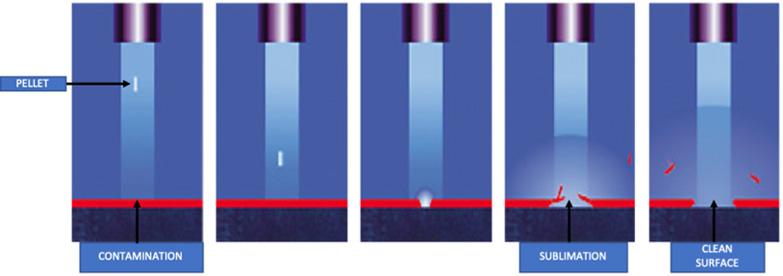

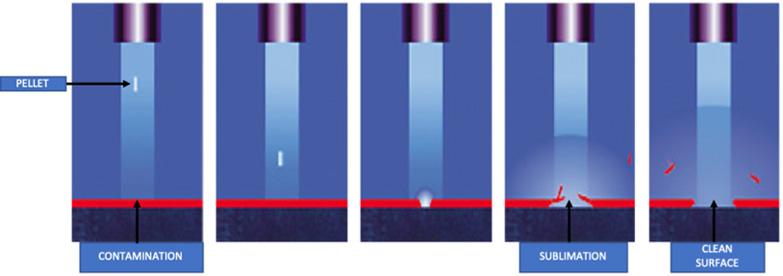

Involves propelling high density rice size pellets at supersonic speed at dirty, dusty, greasy surface at pressure of 50 to 150psi and disintegrating hard layer. Dry ice pallets (-79⁰C) on impact converts to co² gas which expands rapidly under the surface & contaminants fall off.

What are benefis ?

- Faster & more thorough cleaning than scrubbing & wire brushing. It cleans in crevices that can’t be reached by hand.

- Solvent cleaning is eliminated.

- Unlike solvent cleaning, there is no secondary waste disposal. Co2² pellets vaporizes. Solid contaminant is swept away or vacuum cleaned.

- No drying time required.

- Superior & quick clean: Fewer cleaning cycles → less downtime → more profit

- Non-abrasive, nonflammable & nonconductive: Cryogenic cleaning won’t damage most substrate and can be used safely on electrical components even On live Equipments.

Frequently Ask Questions

- What is cryogenic Cleaning?

Co2 gas is first liquefied & than solidified. It's temp is -79C. Dry ice is compressed in hydraulic press to form pellets of the size of rice grain

-

How does it works?

The micro thermal shockcaused by temp. difference of 110C (-79 dry ice + 30 ambient temp.) & the kinetic energy of dry ice pellets and air pressure, produces localized high shear stress between the micro layer which break the bondage between coatings and sub surface. It pops off the coating from inside out and air pressure sweeps it aside.

Where can I use Cryogenic Cleaning?

- Generator stator, rotor & exciters windings

- Turbine blades, diaphragms & casings etc.

- Gears & their accessories

- Electric motor windings & armatures

- Switchgear & cable trays

- Control panels & MCC’s

- Transformers & their bushings

- Substation & line insulators

- Any kind of tyre moulds & other contaminants

- Aviation Industries